Peanut Processing Machinery WhatsApp: 8613954503673 E-mail: sales@xtpeanutmachine.com sales001@xtpeanutmachine.com

Peanut Processing Machinery WhatsApp: 8613954503673 E-mail: sales@xtpeanutmachine.com sales001@xtpeanutmachine.com

Name:Peanut Blanching Machine

Model:XT-TP

Material:SUS304

Voltage: 380V 50HZ 3Phase /220V

Capacity: 500-700kg/h,1000-1200kg/h,2000kg/h..

Advantage:No Powder, NO oil leak, Surface smooth,No consumable parts

Application:Peanut, Hazelnut

Founction:Used for removing the red skin from peanuts

Description

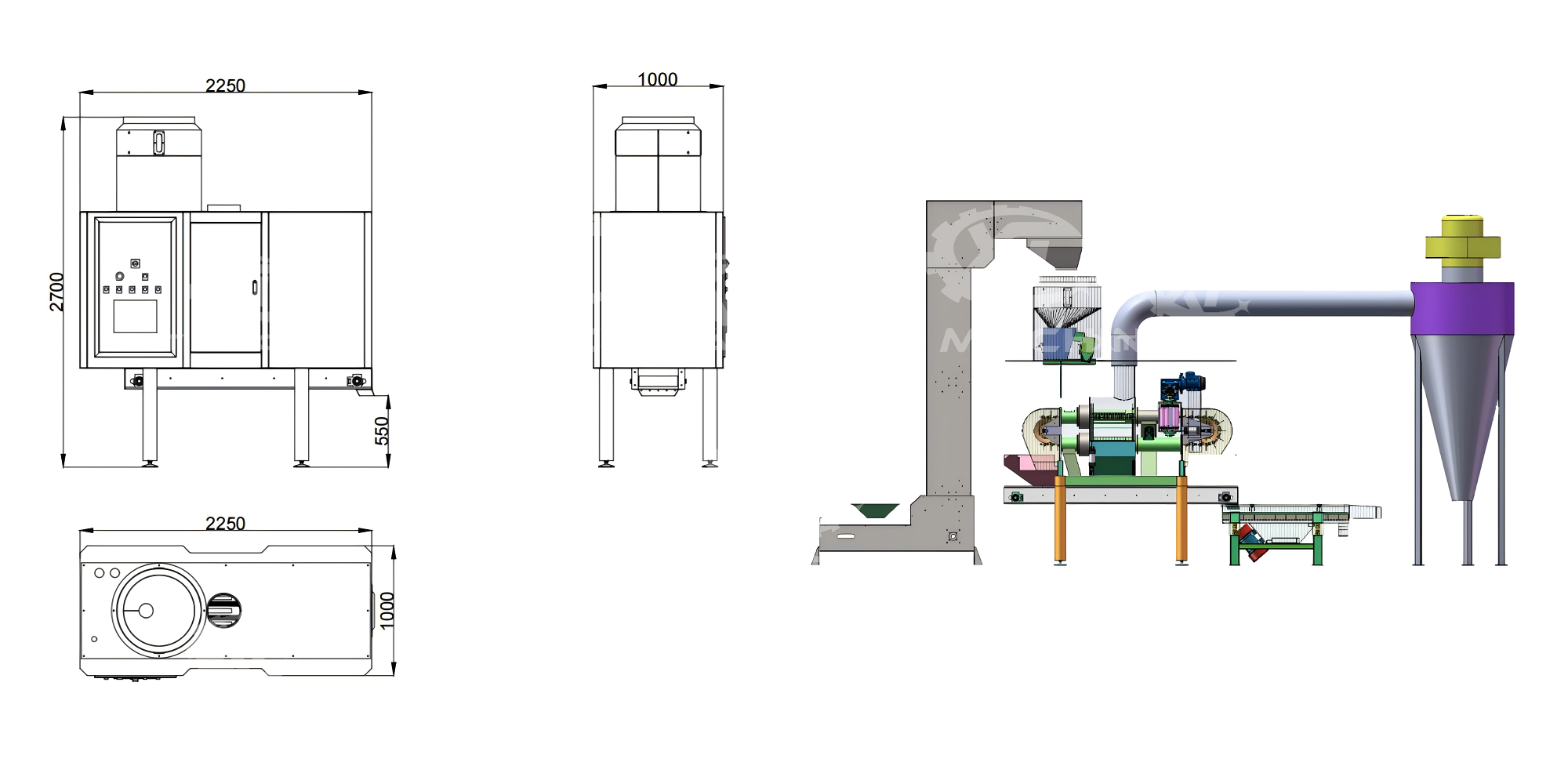

The materials are weighed in the weighing hopper through the feeder, and then put into the peeling drum, which is equipped with spiral pieces. The compressed air blow into the peeling drum to makes the materials roll and rub in the spiral pieces to achieve the peeling result. The powder and red coat produced in the process of peeling under the action of compressed air will enter the primary dust collection room through the air flow, and the dust will be precipitated by the internal rotation of the wind, while the red coat will be collected by cycloneAfter the material is peeled, it will be discharged into the vibrating screen to remove impurities and get the well peeled peanut.

| NO. | Classification of peanuts | Moisture Content | work pressure | Dust Collector(3kw)air volume | Split rate | Blanching Rate | Capacity | Gas consumption | Weight | Size(mm) | Note |

| 1 | Raw peanut | 7-10% | 0.65-0.75Mpa | 3000 cubic wind pressure 1500 | 10% | 85-95% | 0.7± t/h | 9.5m³/min | 850kg | 2250*1000*2800mm | Due to differences in moisture content and size of materials, there may be variations in output and results. Actual results may vary (for reference only). |

| 2 | Dried Peanut | 5-6% | 0.5-0.6Mpa | 10-20% | 95-99% | 1.4±t/h | 8.5m³/min | ||||

| 3 | Full Roasted Peanut | 2-4% | 0.5-0.6Mpa | unlimited | 99-100% | 2±t/h | 7.5m³/min |

Air Peanut Blancher Machine used compressed air as the peeling power, replaces the traditional sand roller peeling machine. The Air Peanut Blancher Machine includes hopper, elevator, receiving bin, automatic weighing device, peeling device, red skin suction device, and discharge vibration sifter, dust cyclone, and air compressor (can be prepared by yourself) The whole set of equipment is divided into 5 parts: feeding system, peeling system, red skin collection system, discharging system, and PLC control system.

The Peanut Blanching Room has a special structure chamber. The main blancher automatically completes the blanching process by blowing and releasing according to program instructions, The surface of the peeled peanut is not damaged, and the peeling rate is as high as 98%. The whole blanched peanut rate is also as high as 85% or more.

Peanut, Hazelnut

REQUEST A QUOTE

We Wanna Hear From You

Navigation

WhatsApp: 8613954503673

Tel: +86 13954503673

E-mail: sales@xtpeanutmachine.com

Add: No.8, Jinshajiang Road, Yantai ETDZ, China

E-mail: sales001@xtpeanutmachine.com

Follow Us